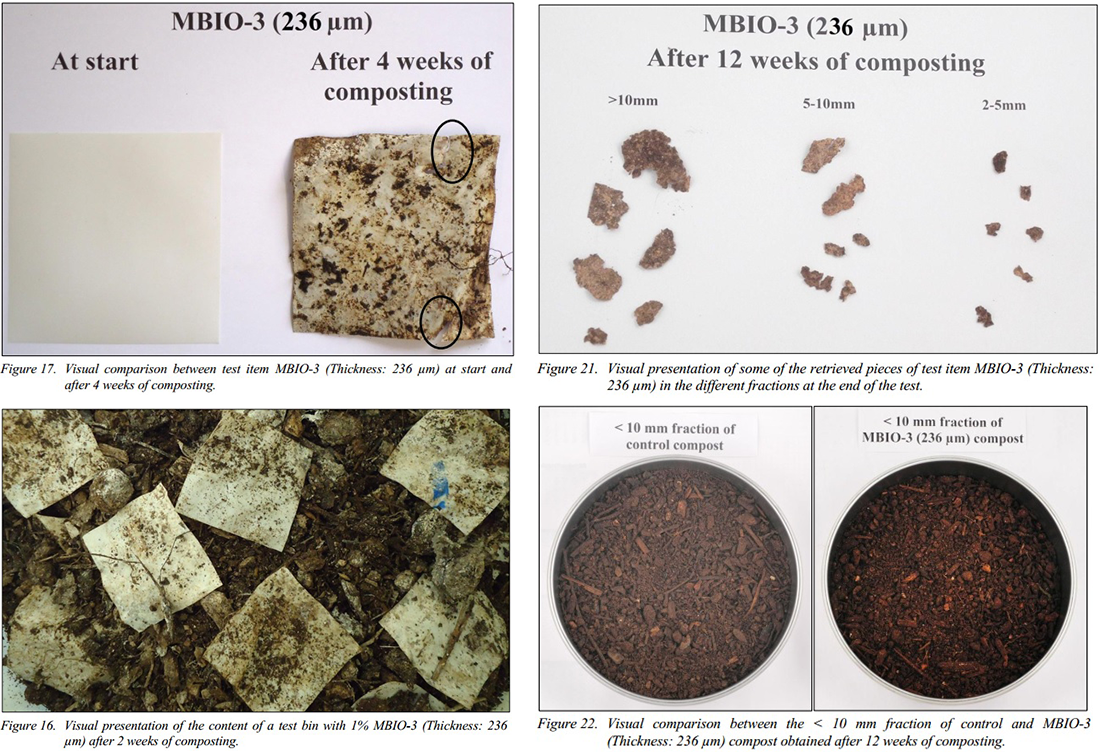

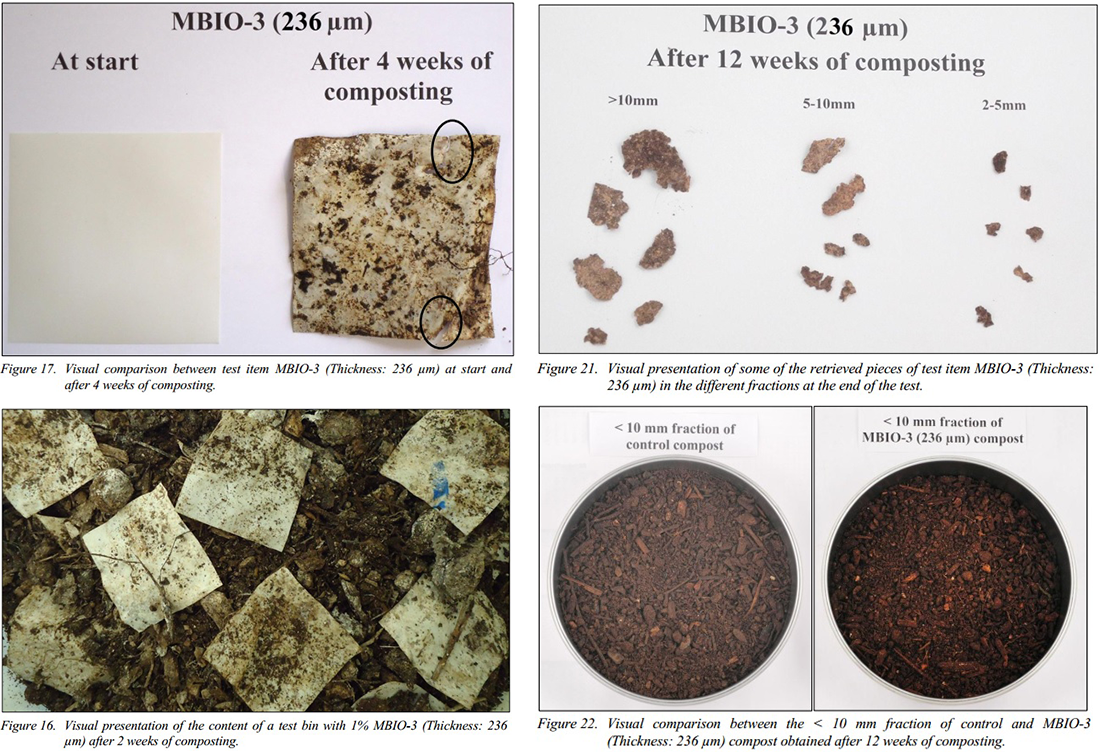

MBIO-3 Film blowing grade biopolymer

MBIO-3 Film blowing grade biopolymer

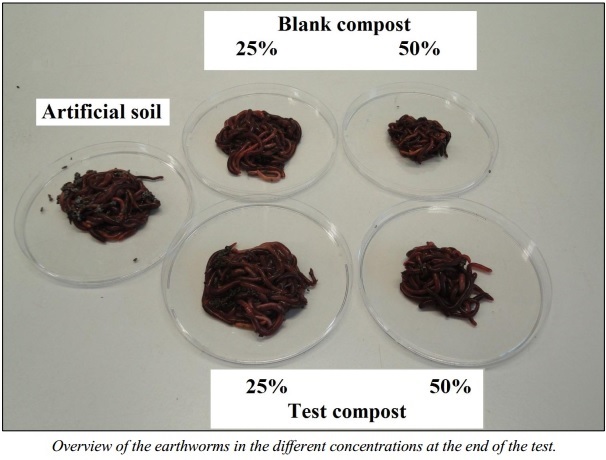

Our MBIO-3 resin & film comply with EN 13432, ASTM D 6400 and AS 4736 standards on industrial composting biodegradability within 180 days, heavy metal residue and ecotoxicity testing. These products have been accredited by international certification bodies (CBs) including TUV , BPI (USA) and ABA (Australia). Besides the total compostable property within 180 days, our biodegradable resin & film are produced under two decades of film production professionalism and expertise, thus, the mechanical properties of our bioplastic products (tensile strength, dart impact, tear resistance and so on) are comparable to petroleum based plastics.

| Our MBIO-3 biodegradable film is good for shopping bag and the collection of biodegradable refuses (maximum thickness is 236 micron). Additionally, we formulate black masterbatch, also biodegradable, for agricultural mulch film application to protect the crop from weed and insects. |

|

|

MBIO-4 Film blowing grade bioplastic

MBIO-4 Film blowing grade bioplastic

Our MBIO-4 resin & film comply with EN 16640 standard with 29% of biobased carbon content. These products have been accredited by international certification body (CB) including TUV. Besides that the product can be produced by traditional plastic film blowing process, our MBIO-4 resin & film are produced under two decades of film production professionalism and expertise, thus, the mechanical properties of our bioplastic products (tensile strength, dart impact, tear resistance and so on) are comparable to petroleum based plastics.

Our MBIO-4 biobased resin & film are good for shopping bag and agricultural mulching film to protect the crop from weed and insects.

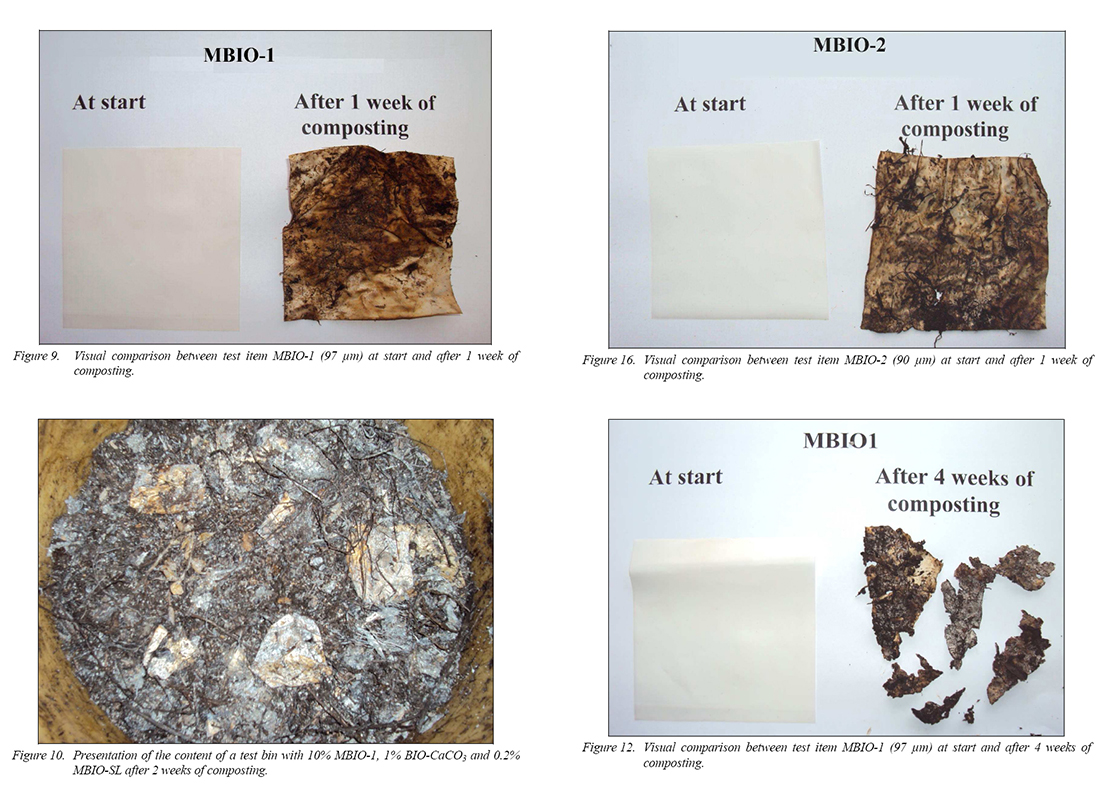

MBIO-1

MBIO-1

MBIO-2 Biopolymer film & bags

MBIO-2 Biopolymer film & bags

MBIO-3 Film blowing grade biopolymer

MBIO-3 Film blowing grade biopolymer

MBIO-4 Film blowing grade bioplastic

MBIO-4 Film blowing grade bioplastic MBIO-5 Film blowing grade biopolymer

MBIO-5 Film blowing grade biopolymer

MBIO-6 Film blowing grade biopolymer

MBIO-6 Film blowing grade biopolymer